The use of ETFE films in architecture

TRANSPARENCY AND LIGHTNESS

ETFE (Ethylene TetrafluoroEtilene) is a transparent plastic material designed to have a long durability for outdoor applications.

ETFE spreaded in architecture in the last 2 dcades thanks to the characteristics of lightness, transparency and economy compared to glass roofs or facades.

Furthermore, thanks to the ease of processing of the film, complex 3d shapes can be made: the same shape would be impossible or very expensive if made out of glass.

Maco Technology has an extensive know-how in the design, construction and installation of lightweight ETFE cushion or single layer envelopes. The multi-layer application of ETFE in cushions allows to cover large surfaces with a minimum weight.

The advantages and disadvantages of using ETFE in architecture

The number of architectural projects with an ETFE roof or facade are constantly increasing, confirming the numerous advantages of this technology.

The lightness of the construction system based on ETFE

The lightness of this construction system is one of the key elements of the success of ETFE structures in architecture. The efficient use of the material, in fact, minimizes the amount of raw material used and leads to a reduction of costs that affect of the entire project and not only the roof or facade subsistems. Thanks to the reduced self weight, the flexibility of the ETFE roofs and the ability to cover large spans, it is possible to optimize the supporting structure by increasing the size of the structural grid and/or reducing the size and thickness of the structural elements.

The seismic behavior of ETFE buildings

Low weight and high flexibility are the key elements that justify the success of ETFE systems in seismic areas. Unlike glass roofs, often severely damaged in the event of an earthquake due to the relatively high weight and the poor ability to absorb large deformations, ETFE systems are optimal solutions for buildings in seismic areas to the point that, for temporary buildings that fall as part of the UNI EN 13782: 2015 standard “Temporary structures – Tents – Safety”, it is not even necessary to carry out an anti-seismic structural verification.

Security of ETFE systems

For public buildings such as stations, hospitals and airports, ensuring a safe building in the most extreme load conditions is one of the designer’s priorities and one of the main objective of the client.

The ETFE envelopes, both with pillows and with a single layer, allow to cover large lobbies and canopies in a safe way, reducing almost to zero the risk of injuries due to splinters or debris in the event of attacks, explosions or any other accidents.

Fire behavior of ETFE films

ETFE films for architecture are classified as class B1 (DIN 4102), B-s1, d0 (EN 13501-1), M2 (NFP 92-505), Pass (NFPA 701) and is universally recognized as an excellent building material from the point of view of fire behavior. The material is combustible but not very flammable and self-extinguishing and, thanks to the melting temperature of 275 ° C, the film is destined to break and shrink before the high temperatures can lead to the collapse of the main structure of the structure. Furthermore, thanks to the consequent ventilation of the rooms below, it is possible to minimize the risk of suffocation due to the concentration of smoke. For special applications where it is essential to ensure ventilation even at low temperatures, there are also patented technologies that allow the controlled opening of the cover modules or the controlled tearing of the ETFE film. In the case of double skin facades, the use of ETFE for the outermost layer avoids the compartmentalization of the facade cladding.

Solar shielding with ETFE film

From the point of view of solar shading, ETFE films allow to customize the optical properties of the transparent film and to reach the shielding levels necessary for internal comfort. The coloring of the film can take place with pigments added during the extrusion phase, with gravure printing and digital printing. It is of fundamental importance to verify the adequate level of shielding at the various frequencies through specific laboratory tests and dynamic simulations of the envelope. The addition of more layers allows to increase the shielding effect and, in the case of cushions with three or more layers, it is possible to control the position of the intermediate films by changing the pressure level in the intermediate chambers and thus creating an adaptive envelope with a relatively low budget compared to other technologies.

For special applications, ETFE surface treatments are also available aimed at reducing the transmission of solar radiation in the IR and UV field.

Thermal insulation

The high transmission of light in the visible and UV spectra makes the ETFE the ideal material to maximize the thermal gains of the envelope during the cold season. From the point of view of thermal insulation, however, the ETFE cladding systems are limited by the poor insulating properties of the material and the reduced thicknesses used. A single ETFE layer has a thermal transmittance U of 5.6 w / m2K which is reduced to 1.96 w / m2K in the case of a three-layer cushion.

Furthermore, in projects that use large cushions, the thermal bridge due to the edge clamping profiles can be considerably reduced.

In the case of applications in area with high concentrations of humidity such as greenhouses, winter gardens and swimming pools, we recommend the installation of additional profiles for the collection of condensate which can easily accumulate at the edge profiles.

Acoustic insulation of ETFE casings

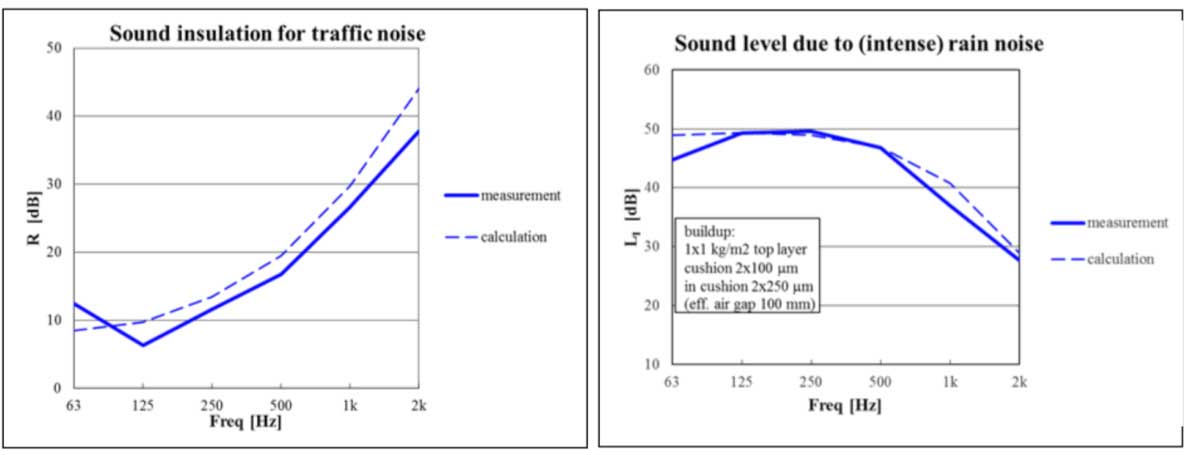

ETFE pillow are a type of light and transparent cover which entails rather low levels of acoustic insulation. Where necessary, it is possible to insert a mesh able to attenuate the noise thanks to the fact that it works as a damper reducing the reverberation in the space below. The aluminum edge profiles can be easily designed so that the mesh can be added at a later time, thus offering the possibility to evaluate the extent of the problem.

Various types of casing have been studied by a team of Dutch researchers who presented the results of the study at the conference of the International Association of Space Structures with an intervention entitled “ETFE cushions as building envelope material – acoustic challenges and developments” from which it can obtain acoustic insulation for noise from traffic and pouring rain.

ETFE applications in architecture

The excellent mechanical and self-cleaning properties make ETFE the ideal material for different applications in architecture

ETFE roof

Since the first application of ETFE in construction at the Burges Zoo in 1982, ETFE roofing has gradually gained market share and is now successfully used in several buildings.

The most used technology consist of two or more layer, inflated with dry air: they are called ETFE cushions. Thanks to an accurate design of the membrane cutting pattern, even the most demanding load conditions can be successfully managed. Wind loads are generally managed through the overpressure of the cushions which can also be controlled in an adaptive way so as to guarantee an internal pressure higher than the external pressure due to the wind, thus avoiding fluttering problems.

In case of exceptional snowfalls with loads higher than the internal pressure of the cushions, the cushions will partially or totally deflate. In this scenario, the ETFE layers overlap each other thus allowing the load to be distributed evenly between the different layers ensuring the coverage and safety of the roof even in extreme conditions. In case of extremely high snow loads or large cushions, it is also possible to add structural support cables, designed to reduce the excessive deformation of the ETFE foils when loaded with snow.

Single-layer systems are not that common as roofing systems due to the risk of excessive elongation of the ETFE outside the elastic range. Systems of this type are generally used in areas with limited snow load and are generally reinforced with support cables.

ETFE facades

Thanks to the absence of snow loads, ETFE facade systems are characterized by a very large geometrical freedom with fewer technical limits due to the risk of water stagnation and the accumulation of snow and ice.

In addition to two or more layer cushion systems, modular panel systems or double-curved single layer systems can be successfully used.

As for the roofs, also in ETFE façades it is possible to integrate ropes or nets of support ropes that allow to guarantee the construction system even in tropical areas with winds over 36 m / s.

One of the key advantages of using ETFE for facade systems is the possibility to obtain complex three-dimensional shapes at a low cost, especially if compared to glass facade systems.

Greenhouses and wintergardens in ETFE

Greenhouses and wintergardens are one of the most natural applications of ETFE systems thanks to the high transparency of the material, even in the spectra of solar radiation generally shielded by glass panels.

In addition to optimizing thermal gains in the winter season, the high transparency of ETFE allows to increase the yield in fruit and vegetable cultivation by reducing the use of chemical treatments thanks to the fungicidal action of ultraviolet radiation from sunlight.

In addition to the greater transparency of the covering film, there are also the advantages of a less bulky support structure that reduces the shade on the underlying crops.

The Eden Project in Cornwall is certainly the best known example of an ETFE greenhouse but the system can also be used successfully for less expensive applications in agriculture allowing the rapid and efficient replacement of glass panels or traditional plastic films.

Art installations with ETFE

Digital printing created new opportunities and different possibilities of customization of ETFE films which has therefore become an alternative to PVC or PU films for applications that require better performance in terms of mechanical strength and ageing when exposed to run rays.

Recent applications of art installations include the Coca-Cola Beatbox pavilion for the London 2012 Olympics (Asif Khan and Pernilla Ohrstedt), the 2015 Serpentine Gallery pavilion (SalgasCano) and the artistic installation

Invisible Borders per il Fuorisalone di Milano 2016.

Retrofitting and improvement of existing buildings

Thanks to the lightness and flexibility of ETFE film systems, it is possible to retrofit existing buildings by improving their aesthetics and thermal performance without compromising their structural behavior. The extremely low self wieght per surface unit (2-3.5kg/m2) do not incrrease the structural stresses in case of an earthquake and, at the same tim,e reducing the risk of debris from detaching from the facade or from the roof, injuring passers-by.

Temporary structures in ETFE

Temporary structures such as pop-up shops, fairs or traveling events are generally made of PVC fabrics and films due to the flexibility of the material.

However, the recent experience of the itinerant pavilion for the Yamaha MotoGP hospitality area has highlighted the feasibility of modular ETFE facades also for itinerant structures and for temporary architecture traditionally made with materials other than ETFE.

Examples of ETFE architecture:

The construction system and technological aspects

Single and double aluminum profiles

The ETFE casings are designed and manufactured using 3D software, cutting tables and welders that guarantee a high level of precision completely different than standard tolerances in the construction world. The most practical way of integrating the ETFE system into a traditional building is the use of aluminum profiles that allow you to install the ETFE membrane with ease and precision and manage any tolerances through the attachment system to the substructure, generally made on flanges anchoring with T shapes. For special applications, the profiles can be designed with a thermal break that reduces the risk of thermal bridges.

Support flanges for assembly and rapid maintenance

The aluminum profiles are mounted on the support substructure by T or C flanges (upstands) welded on the support structure or fixed to the main structure in wood or reinforced concrete by means of special dowels.

This detail, often in combination with slotted holes, allows you to manage any errors in the substructure, also offering the possibility to remove portions of the structure in case of routine maintenance.

In the case of wooden structures, the interspace between the roof and the structure allows the wooden structure to be ventilated and kept dry even in the event of condensation or minor infiltrations.

Seals for water tightness

The hermetic seal of ETFE solutions is guaranteed by gaskets that prevent the infiltration of air and water. In the case of applications in buildings with a risk of condensation (greenhouses, winter gardens, swimming pools and crowded places) it is recommended to install an internal gutter for the collection and disposal of any condensation.

Blowers, filters and dehumidifiers

The pressure of the cushion systems is guaranteed by a system consisting of a blower that guarantees the overpressure of the cushions with an very limited air flow. This allows low energy consumption and it is possible to keep large pillow roofs under pressure with a minimum quantity of energy. For medium-sized roofs, the inflation unit has a footprint of about one cubic meter which increases if emergency blowers, special filters or air dehumidifiers need to be installed.

Valves and ventilation ducts

The pressurized air is distributed through a system of pipes with a diameter between 10-15 cm (main duct) and 4 cm (branch for the single cushion).

The pipes of the pressurized air are connected to the cushion by means of special aluminum valves which are mechanically fixed to the ETFE film during the welding phase. In some areas of the pillows, overpressure valves are generally inserted which guarantee the periodic recirculation of air in the cushion while ensuring that the pressure limit will not be exceeded.

ETFE Pillow

The environmental impacts of ETFE

Recyclability and environmental impact

ETFE films are 100% recyclable and can be used to make products for industry such as pipes and valves without particular aesthetic and transparency requirements.

Due to the useful life of the ETFE film (50-100 years) the quantities of recycled material are extremely small and most of the recycled material currently comes from the processing waste of the new films.

As for aluminum profiles, despite the high energy incorporated, the environmental impacts are mitigated by the durability of the material and the ease with which it can be recycled without compromising its properties.

Durability

ETFE systems are generally comes with a guarantee that protects the customer from possible defects in the various components or from incorrect assembly. We recommend to sign a maintenance contract with the supplier in order to extend the life expectancy of the entire roof or facade.

Thanks to its extraordinary resistance to UV radiation, pollution and meteorological agents, the ETFE film has an expected life between 50 and 100 years, much longer than traditional plastics. When installed in architecture, the life spans expected is between 20 and 25 years.

Environmental Product Declaration

In the literature there are several studies on the impacts of ETFE on the environment including LCA studies (Life Cycle Assesment) and EPD declarations (certified environmental product declaration).

ETFE is classified in class II by the Montreal Treaty with minimal damage to the ozone state. ETFE production takes place by transforming the TFE monomer into the ETFE polymer through a water-based polymerization process without the use of solvents. The material is then extruded in various thicknesses through an extrusion process that requires the use of minimal quantities of energy as well as the cutting and welding operations of the ETFE rolls for the packaging of the finished product.

The regulatory aspects

TensiNet guidelines for ETFE structures

The European association TensiNet has published an appendix to the guidelines for tensile structures (Annex 5: Design Recommendations for ETFE Foil Structures, 2013) specifically dedicated to the use of ETFE in architecture and construction.

Towards an Eurocode for tensile structures

In 2016 a team of academics and representatives of the tensile structure industry published a report entitled “Prospect for European Guidance for the Structural Design of Tensile Membrane Structures” in order to support the implementation, harmonization of current guidelines and the future development of a Eurocode for tensile structures.

The document includes recommendations for pneumatic structures and ETFE structures of great interest for engineers and architects who intend to approach this type of structure.

Maco Technology srl

We operate in the textile architecture sector alongside sensors and electronics in order to create adaptive structures.

We design, build and install lightweight structures based on unconventional materials such as fabrics, films and composite materials. We are able to assist our customers from preliminary design through to construction through prototypes and mechanical tests.

Info and Contacts

Telephon: +39 030 9823 869 – E-mail: info[@]macotechnology.com