Design and construction of Textile Façade and Textile Architecture

Outdoor cladding in textile and ventilated facades

What is a textile facade?

Textile facades are a dry assembled prefabricated building system. Usually, textile facades consist of a textile covering and a metal structural substructure fixed to the main (existing) structure of the building.

Different types of textile facade are available: typologies changes according to the connection system of the textile covering. The most widely used are single-layer or double-curved solutions, tensioned on site. An alternative is the modular panel systems. Pneumatic systems are a soltion too.

The textile facades allow to protect the building from atmospheric agents and can be applied to new buildings or existing buildings in order to achieve specific aesthetic and performance targets.

In this guide we will talk about:

The advantages and disadvantages of textile facades for architectural and engineering projects

Compatibility with other materials

Textile systems for architecture are characterized by a high accuracy in the production phase that allows an easy combination with traditional building systems . The high flexibility of the cladding and the support structure minimizes the risks of damage to the existing facade due to deformations induced by thermal expansion that often lead to damage of rigid glass or ceramic material panels.

The textile materials guarantee an exellent corrosion resistance for external applications and are fixed to the supporting structure by means of anodized aluminum profiles which minimize the risk of corrosion. The supporting structure is generally in steel and protected by a layer of powder galvanizing and painting applied after the sandblasting of the metal profiles.

Different alternatives: fixed panels or retractable shading devices.

The wrapping textile systems are not limited to fixed solutions but can be used for solar shading based on mobile panels or roller blinds.

Facade cladding

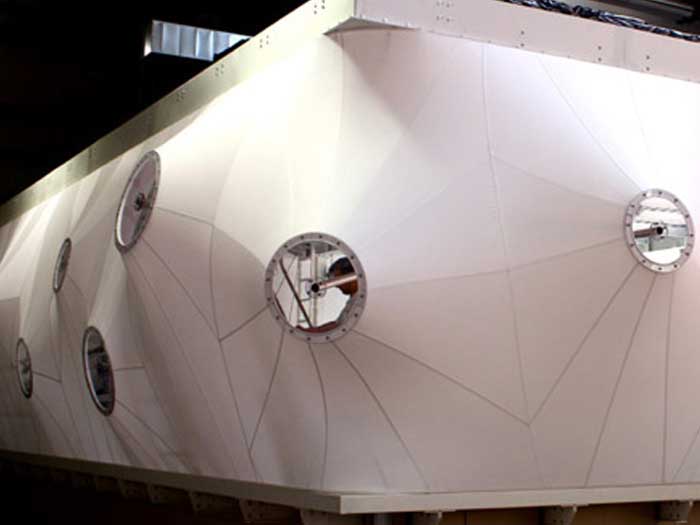

Textile facades allow you to cover buildings effectively even in case of complex three-dimensional shapes . The form-finding process, that is the determination of the form, takes place through sophisticated calculation algorithms based on the digital 3D model of the support structure.

The type of facade cladding and the materials used allow to improve the image of the building and to meet specific performance requirements related to the shielding of solar radiation, protection from rainwater and thermal insulation.

Textile architecture, a new image for the building

The use of a textile facade allows to obtain a top quality aesthetic result at low costs . The freedom of forms allows to characterize a new project with a technologically innovative solution in line with modern construction standards. In the case of retrofitting on the existing building heritage, textile facades offer an effective solution to renew the image of the building by integrating solutions such as digital printing and LED backlighting avoiding bulky and massive supporting structures.

The properties of technical fabrics for architecture

Fire resistant

Technical fabrics for textile architecture are mainly coated fabrics based on weft-warp support. Fire resistance mainly depends on the type of substrate (fabric) and the type of coating (external coating).

Here are the main classifications for the most used fabrics:

-

- PVC facades: PVC coated polyester fabrics: B-s2, d0 EN 1350-1; B1 DIN 4102-1; BS 7837; Test2 NFPA 701; CSMF T19

- PTFE-glass fiber fabrics : B-s1, d0 EN 1350; Class A ASTM E108

- Silicone coated glass fiber fabrics : Class 0 BS 476: Part 6: 1989, Part 7: 1997; B1 DIN 4102

- Polyester fabrics coated in PU : B1 DIN 4102

- Open mesh fabrics (net) in PVC coated polyester : B-s2, d0 / EN 13501-1; M1 / NFP 92-507; B1 / DIN 4102-1; BS 7837; BS 5867; Schwerbrennbar Q1-Tr1 / ONORM A 3800-1; Class 1 / UNI 9177-87; M1 / UNE 23.727-90; VKF 5.3 / SN 198898; 1530.3 / AS / NZS; G1 / GOST 30244-94; Method 1 / NFPA 701; CSFM T19; Class A / ASTM E84; Group 1 / AS / NZS 3837; Class 1 / EN 13773; CAN / ULC-S109 –

- ETFE film: B-s1, d0 EN 1350; Class A ASTM E108

Protection of the support fabric from UV rays, abrasions, fungi and molds

The structural performance of technical fabrics coated for architecture mainly depends on the support fabric (fiber, number of threads, type of weaving). However, in order to maintain the original mechanical performance, the coating and any surface lacquering have a fundamental role .

The thickness of the coating, which in the case of PVC varies between 80 and 160? M, allows you to protect the threads from UV rays, abrasion and contamination by polluting and organic substances. For specific applications in environments with a high risk of mold and fungus, in the case of polyester, the support fabric threads are previously treated with Low Wick treatments to reduce their proliferation within the fabric (ISO 846 A).

Resistance to violent impacts

If necessary, the façade system can be tested developed by CWCT (Center for Window and Cladding Tecnology) in technical guidelines number 76 “Impact performance of building envelopes:

method for impact testing of cladding panels “. The system is verified up to steel balls of 50kg and an energy of 400 Joules.

Resistance and lightness

The coated fabrics for textile architecture offer a wide range of tensile strengths able to meet the most varied needs, from temporary applications in textile architecture for small temporary installations to the demanding tensile structures used for the facades of large stadiums and sports facilities.

Here are the main tensile strengths for the most used fabrics:

-

- Polyester fabrics coated in PVC: 2,000-10,000 N / 5cm

- PTFE-fiberglass fabrics: 1,000-8,000 N / 5cm

- Silicone coated fiberglass fabrics: 1,000-5,000 N / 5cm

- Polyester fabrics coated in PU: 1.300-2.300 N / 5cm

- Open mesh fabrics (net) in PVC coated polyester: 1,500-5,000 N / 5cm

</ Ul>

Durability and life expectancy

The materials dedicated to textile architecture allow to calibrate the duration and life expectancy of the materials used, according to the useful life of the project . These aspects have a significant impact on the environmental impacts, on the end of life scenarios and on the environmental certifications of the project (LCA, BREAM LEED and CEEQUAL). For temporary projects we recommend easily recyclable materials, preferably single-component, in order to minimize environmental impacts. For permanent projects we recommend instead more durable materials, such as fiberglass-PTFE fabrics or ETFE films, capable of balancing the inevitable environmental impact with a longer duration over time.

Here are the life expectancy for the most used fabrics/film:

-

-

- PVC coated polyester fabrics: 15-20 years

- PTFE fiberglass fabrics and ETFE: 25 years

- Silicone coated glass fiber fabrics: 20 years

- Polyester fabrics coated in PU: 5-10 years

- Open mesh fabrics (net) in PVC coated polyester: 10-15 years

-

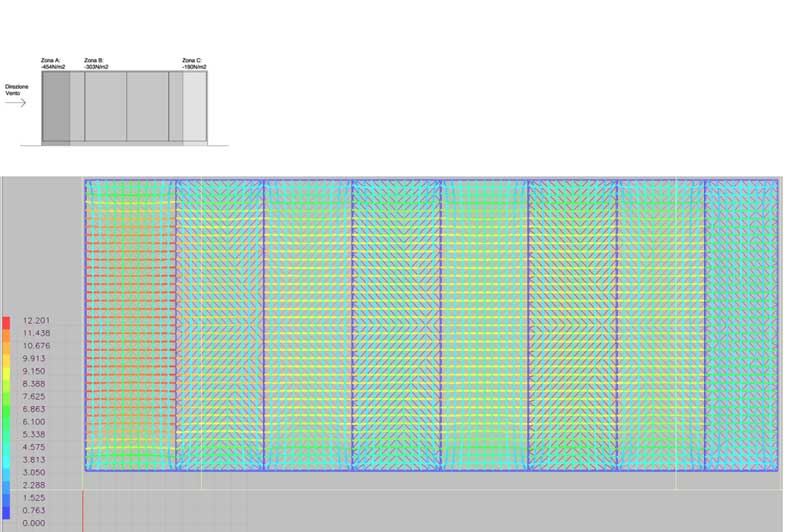

Performance against wind loads

A textile panel system for facades of existing buildings or new projects behaves like most of the facade cladding by transferring the actions of the wind to the main structure of the building . In the case of non-modular solutions, on the other hand, the fabric is applied to a metal support structure and pre-tensioned by means of tensioning systems positioned along the perimeter of the facade. In this case, forces concentrate at the perimeter profiles which must be designed accordingly. In case of modular panel system, these forces are strongly reduced. If properly designed, 2.5m x 2.5m panel systems in coated fabric can withstand design pressures up to 630daN / m2 and can therefore be applied almost everywhere in Europe.

Why textile facade in the right chice?

Cost-effective creative freedom

The application of textile facades on existing buildings allows the aesthetic renovation of buildings that need a new look . In this way it is possible to renew the aesthetic image of old buildings through the installation of a textile façade, tensioned through aluminum profiles.

The job implies the application of very small additional loads to the existing building, reducing the risk structural reinforcments on the existing masonry. In the areas with high earthquake risk, the lightness and flexibility of the system allows you to easily overcome the structural checks imposed by the current anti-seismic legislation.

Thermal comfort and sun protection

One of the main reasons for installing a textile facade is the control of thermal comfort inside the building thanks to adequate sun protection. The wide range of fabrics and shading nets allows to satisfy the transmission, reflection and absorption parameters defined during the design phase.

Controlling the level of solar lighting in the interior spaces

In case of glass enclosures, particularly critical from the point of natural lighting, textile cladding can be applied to mobile winding or paneling systems that can be moved by automatic or computerized systems designed to manage daily and seasonal peaks of radiation.

Print and aesthetic effect

Most of the fabrics for textile facades can be printed with digital technology thus allowing a total customization of the surface. In the case of complex shapes, during the design phase the graphic image is applied to the 3D surface and modified so as not to have substantial optical deformations. In the realization phase, dedicated modeling software allows to divide the print pattern so that it can be printed on the rolls of fabric used for the facade cladding.

Quick solutions produced with a modern and innovative technology

The construction sector in not the early-adapter for new technologies and innovations. The textile facades represent a rare exception in the current panorama thanks to a very precise and efficient production method.

The design phase, with the only exception of the architectural models for the initial concept, takes place through sophisticated CAD software for modeling and determination of the froma (form-finding). The 3D geometry is then divided into smaller portions according to the height of the fabric roll used. The cutting lines follow the geodesic line between two points, that is, the shortest curve that connects two points on a surface. Once sectioned, the surface is flattened using geometric techniques that minimize errors and distortion of complex initial geometry. The cutting panels are finally cut by means of computerized cutting plotters and suitably welded / sewn in order to reconstruct the initial 3D geometry. The final installation, which can be preceded by a mock-up for approval by the client, takes place in a simple and safe way by minimizing the work on site and by means of lifting equipment easily available on the market.

Acoustic well-being and safety

Recently, attention to acoustic well-being in the interior of buildings has grown significantly. Despite the poor insulating properties of the fabrics from the acoustic point of view, the main manufacturers have developed products which hase value from the point of view of the sound absorption. Open mesh fabrics or micro-perforated films are nowadays used for internal applications such as false ceilings or absorbent panels. The energy of the acoustic wave is absorbed and dissipated thanks to the vibration of the fabric and the passage of air between the holes and the meshes of the fabric. The system becomes particularly effective when cupled with insulating mats.

Examples of textile facades and exterior cladding

Stitched Tenara facade

Maco Technology srl

We operate in the textile architecture sector alongside sensors and electronics in order to create adaptive structures.

We design, build and install lightweight structures based on unconventional materials such as fabrics, films and composite materials. We are able to assist our customers from preliminary design through to construction through prototypes and mechanical tests.

Info e Contacts

Telephone: +39 030 9823 869 – E-mail: info[@]macotechnology.com